Introduction of Double Mode Extrusion Granulator

The double mode extrusion granulator is a collection of flat die extrusion technology, ring die extrusion technology, and screw extrusion technology.

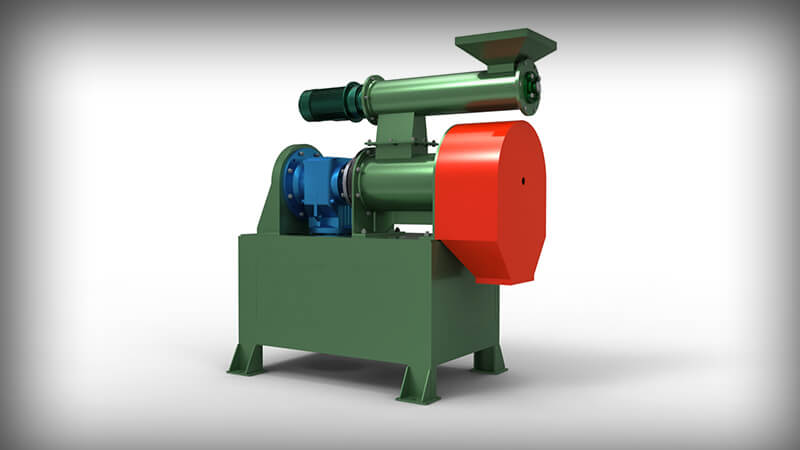

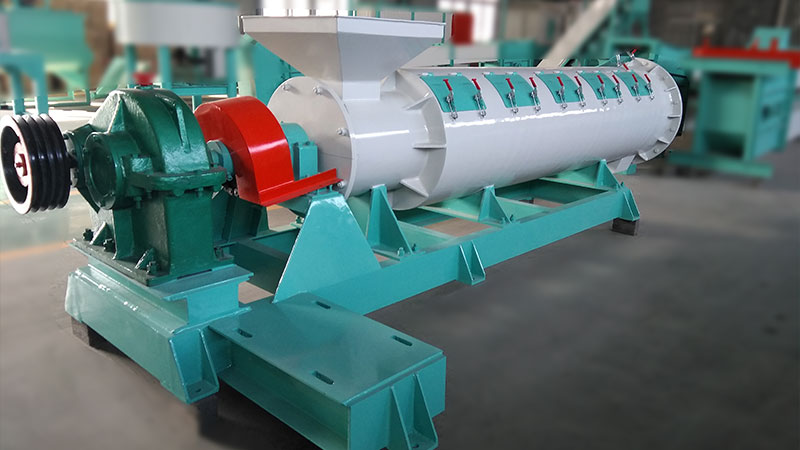

Structure of Double Mode Fertilizer Pellet Mill

Double mode fertilizer granulation machine includes Control System, Granulator, and Feeder.

1. Feeder, consisting of hopper, PID controlled spiral auger, and frequency conversion motor, is installed above Granulator. PID controlled spiral auger is driven by frequency conversion motor, one side of which connects with the feeder, there is being discharge hole on the other side.

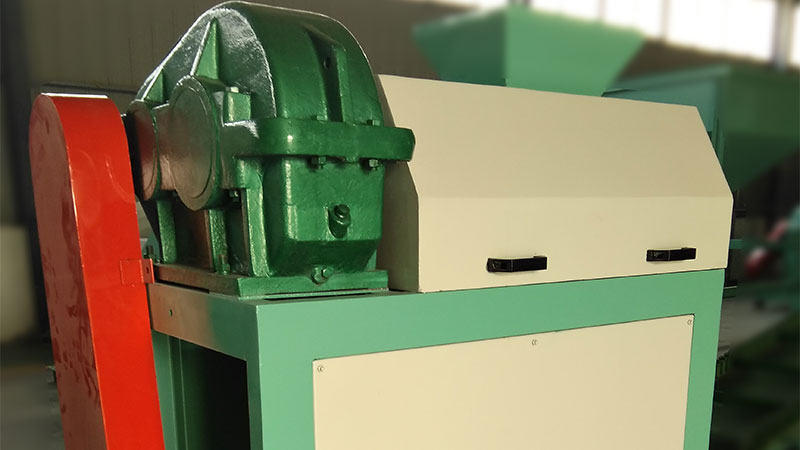

2. The granulator machine consists of main motor, reducer, coercion conveyor screw auger, radial roller, axial roller, annular die and flat die.

● The output shaft of main motor connects with reducer whose output shaft links with the main spindle of coercion conveyor screw auger by couplings.

● Top of one side of the coercion conveyor screw auger has feed inlet connecting with the discharging hole of the feeder. On the other side, there are radial roller and axial roller being installed orthogonally on the main spindle.

● Annular die and flat die, on the lateral border of radial roller and axial roller, are fixed on the frame of the fertilizer granulator machine.

● There are discharging holes on the dies. A discharging port is set below the dies.

3.Control systems consists of current transformer, intelligent ammeter, frequency converter, and external power supply.

● Output of carry current of granulator main motor is through current transformer whose current signal output end connects with the current transmitter signal input end of intelligent ammeter.

Transmitter signal output end of intelligent ammeter connects with transmitter input end of frequency converter whose power output end connects with source input pin of frequency converter. Inverter and main motor of the fertilizer granulator part connects with external power supply.

Advantage of Double Mode Fertilizer Granulator Machine

Double mode fertilizer pellet mill adopts bi-directional rolling technology and double mode granulation technology. PID automatic feeding control system makes sure the high efficiency and high reliability of granulation system.

2.High yield

Organic materials are rolled and crushed in granulation sector, which strengthens physical granulation pressure. Compared with conventional extrusion granulator, its granulation efficiency increases by 1-3 times, power consumption reducing by over 60%.

3. Reasonable structure

This organic fertilizer granulation machine is with simple structure, less wear, and low breakdown rate. All dies is convenient to install and remove. Template loss cost is greatly reduced.

Application of Double Mode Fertilizer Granulation Machine

It has a wide raw materials application. Organic waste, such as filter mud, alcohol, starch, animal husbandry, can be granulated into organic fertilizer and bio fertilizer. This fertilizer granulation machine is widely used not only in organic fertilizer production process, but in food, feed, bio-fuel and other chemical industry.

Technical Data of Organic Fertilizer Granulation Machine

|

Model

|

Dimension(mm)

|

Production Capacity(t/h)

|

Power(kw)

|

|

AZS-SMZL-40

|

1760x960x1850

|

3-7

|

30

|

|

AZS-SMZL-60

|

2130x1000x2380

|

5-10

|

45

|