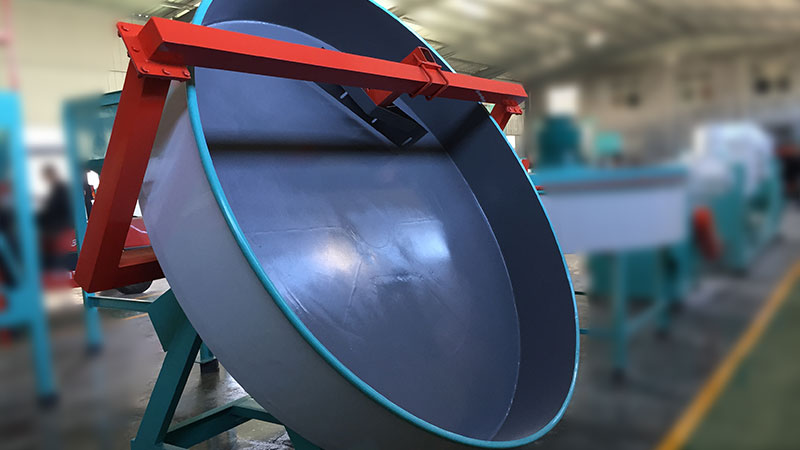

Different from rotary drum granulator only being used for compound fertilizer manufacturing, pan granulator can be used to produce not only compound fertilizer, but organic fertilizer, being one of the most important fertilizer granulating equipment nowadays.

Features of Disc Pan Granulator

1.The flat pan adopts circular arc structure, promising 93% compound fertilizer yield.

2.The disk uses strong iron material, sturdy and durable. Due to strong, stable and lasting base design, there is no need fixing the base with Anchor Bolt.

3.The inside lining of the pan adopts high strength and strong corrosion-resistance plastics glass, with simply structure, high fertilizer granules yield, and easier to maintenance.

4.This fertilizer granulator machine is stable and reliable in operation, low noise.

5.It is used in our compound fertilizer production line, such as our tailor-made 50,000 tons/year compound fertilizer production line.

Working Principle of Disc Pan Pelletizer

Pan granulator consists of Disk and Base. The disk, angle of which is adjustable, is at a slant, dipping to the ground. Evenly-blended materials are uniformly added into the disc (with a dip angle of 35-55 degrees ) which trundles the raw materials. Percussion and friction between materials increase with the rotation of the disk. The particles in the disc change from small to large, then forming into fertilizer granules for some time.

Application of Disc Pan Fertilizer Granulator Machine

This fertilizer granulating equipment is widely used in organic fertilizer production line, and compound fertilizer production line. It also suits chemical, pharmaceutical, metallurgy, building materials, fodder industry. This fertilizer granulator machine is with simple structure, and easy for adjustment, which is suitable for processing raw materials with particle size no more than 50mm. It is not appropriate to transport materials with large viscosity.

Structure of Pan Granulator

1.Frame part

Since the drive part and rotating part of the whole body all are supported by the frame, the frame part is constructed with strong and quality channel steel, which has achieved the purpose of this fertilizer machine manufacturer.

2.Regulating part

The most important part of the disc granulator is Pelletizing Disc, the entire focus of which is on installation and regulating part. Therefore, our factory weld the components of the machine together with the use of excellent carbon steel plate and channel steel.

3.Transmission part

It is a very essential part of the whole granulator. The motor and reducer installed on the adjustable bracket, are all quality-inspection-free products with ISO Quality System Certification. Motor drives pulleys, reducer and pinion. Pinion drives main drive gear to getting the pelletizing disc to work. Besides, the pinion and main gear adopt high frequency quenching, prolong their service life twice longer than before. Entire granulation plate is fixed on the adjustable bracket, stigma coupling part with taper coordinated structure, more reasonable.

4.Automatic cleaning section

The automatic materials-cleaning part is installed above the granulation disc. There is cleaning board on it, which is more convenient to remove materials sticking to the bottom. All those reasonable design greatly improve the life of the disc granulator, saving labor at the same time.

Technical Data of Disc Pan Fertilizer Granulator

|

Model

|

Disc diameter (mm)

|

Disc edge height (mm)

|

Speed (r/min)

|

Dip angle

|

Electronic power (kw)

|

Throughput (t/h)

|

|

ZL5

|

500

|

160

|

35

|

30°-60°

|

0.75

|

0.2

|

|

ZL10

|

1000

|

200

|

32

|

30°-60°

|

1.1

|

0.6

|

|

ZL15

|

1500

|

300

|

20

|

40°-55°

|

3

|

0.8-1

|

|

ZL20

|

2000

|

350

|

16

|

40°-55°

|

4

|

1-2

|